Articles

Knowledge Center

4PL: Definition, How it Works, and Benefits

Global supply chains are no longer simple. Businesses now manage hundreds of moving parts across multiple countries, from sourcing to shipping orders, tracking inventory, and handling freight forwarding. Distribution and fulfillment centers serve as strategic hubs in the supply chain, where inventory is stored, managed, and shipped to optimize logistics efficiency. Without the right system, […]

Read More

Circular Supply Chain: Definition, Components, and Benefits

Linear supply chains no longer meet the needs of today’s global economy. High waste, resource shortages, and frequent supply chain disruptions make it harder for companies to operate efficiently. Businesses need smarter systems that recover value and reduce dependence on finite resources. A circular supply chain offers a better way forward. As part of the […]

Read More

The Top 20 Fleet Management Challenges Faced By Owners and How to Overcome Them

Solving fleet management challenges helps fleet managers reduce fuel costs, lower maintenance costs, and improve driver performance. Tools like GPS tracking, route optimization, and telematics systems enable smarter, informed decisions.

Read More

End-to-end Supply Chain: E2E Meaning, Benefits, & How to Implement

Adopting an E2E supply chain ensures businesses stay competitive by optimizing workflows and strengthening supply chain planning. The ability to track performance across the supply chain end enhances adaptability and customer satisfaction.

Read More

5 Types of Risk in Supply Chain Management

This guide breaks down five types of risk in supply chain management, showing how environmental risks, financial threats, and market shifts can hit operations hard.

Read More

Types of Cargo: Key Factors, How They’re Transported, and Handling Requirements

Cargo means goods or products moved from one place to another for cargo transportation. In the shipping industry and global trade, understanding different types of cargo helps optimize how goods reach their destination. Businesses rely on shipping companies and logistics companies to handle bulk cargo, liquid bulk cargo, general cargo, and more. Proper transport vehicles […]

Read More

Supply Chain Resilience: What It Is, Common Disruptions, and How to Build

Supply chain resilience refers to a company’s ability to prepare for, respond to, and recover quickly from unexpected disruptions. Businesses now face constant challenges like natural disasters, geopolitical risks, and the lasting impact of the COVID-19 pandemic. These events expose weaknesses in even the most efficient supply chain models. Supply chain leaders are under pressure […]

Read More

The Best Mapping Software for Location Intelligence

Choosing accurate mapping software is essential for businesses that use location intelligence. This field has seen steady growth. The global market is projected to reach $63.8 billion by 2032, with steady demand from retail, logistics, and urban planning. Maptive stands out as the best mapping software for location intelligence due to its precision, speed, and […]

Read More

Vendors vs Suppliers: The Differences and Why It Matters

Vendors and suppliers are both business entities that play different roles in the supply chain. Suppliers provide raw materials, while vendors sell finished products to other businesses or the final customer, operating in distinct capacities depending on the products’ use and sales channels. The key difference lies in what each business entity provides to the […]

Read More

Operational Risk Management: Core Principles and Practices

Modern business operations face rising complexity from cyber threats, supply chain issues, and failed internal processes. Each mistake or delay increases risk exposure and disrupts performance. Without a structured system, risks multiply fast and often without warning.

Read More

Global Supply Chain: What It Is, Importance, and Challenges

Studying the global supply chain reveals how products move from raw materials to finished goods across multiple countries. It connects manufacturing operations, distribution, and customer demand in a vast worldwide system. Many global supply chains involve complex steps and working relationships with foreign suppliers to meet the needs of international customers. Breaking down how global […]

Read More

What is Linehaul: Definition, How it Works, and Importance

What is a line haul? It refers to the transport of goods between two points, such as cities, ports, or even warehouses. Line haul transportation covers the long-distance part of the shipping process. It moves freight between hubs like sorting facilities or distribution centers, with the final destination being the endpoint of the shipping process, […]

Read More

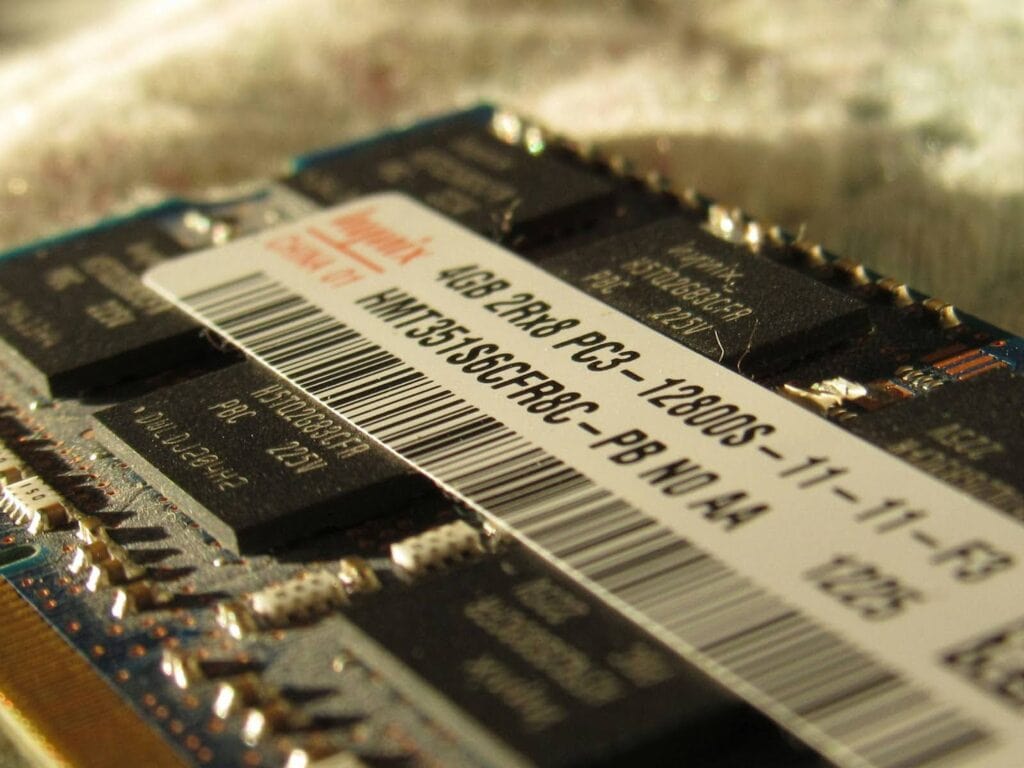

UPC Meaning: What It Is, Types, and How to Get

Running a business today means staying organized, especially when selling products globally or across online marketplaces. Mismanaging items leads to errors, confusion, and lost sales. That’s where understanding UPC meaning becomes essential. A UPC—short for Universal Product Code—is a unique number and a type of bar code used for product identification. The barcode symbol, which […]

Read More

What is Supply Chain Forecasting? Best Methods, Benefits, and Challenges

Uncertainty hurts business. When companies don’t know what’s coming next, they overstock, underdeliver, and miss sales targets. Poor planning can wreck supply chain operations, increase costs, and frustrate customers. Supply chain forecasting refers to the process of predicting demand, supply, or pricing for products within an industry, using data from suppliers to anticipate stock availability […]

Read More

What is LIFO? Definition, Benefits, and Real World Use of Last In, First Out

Inventory valuation shapes how businesses report profits and manage taxes. The LIFO method—Last In, First Out—assigns the cost of the most recent purchases to the cost of goods sold, often reducing taxable income when prices rise. LIFO is one of several cost flow assumptions used in inventory accounting to determine how inventory costs are allocated […]

Read More

Everything You Need to Know About Demand Forecasting: Types, Methods, Benefits and Examples

Businesses need to stay ahead in a fast-moving market. Strong demand forecasting helps companies make better decisions, reduce risk, and stay ready for sudden changes.

Read More

Inventory Planning: What It Is, Importance, and Challenges

Running out of stock or holding too much inventory can ruin profit margins, cause customer dissatisfaction, and throw operations off balance. Businesses that ignore planning often face lost sales, cash issues, and wasted storage space. Whether managing a retail store, manufacturing line, or online shop, one thing is clear: inventory planning is not optional. Smart […]

Read More

Top 20 Essential Fleet Management Strategies for Maximum Efficiency and Safety

Managing a fleet without a clear plan often leads to chaos—higher fuel costs, increased vehicle downtime, and frustrated fleet managers. Strong fleet management strategies act as the foundation for smarter, safer, and more cost-effective fleet operations. These strategies cover everything from vehicle maintenance and driver behavior to fuel efficiency and operational efficiency. With the […]

Read More

Inventory Forecasting: Formulas, Methods, Benefits and How to Implement

Running out of stock during peak demand or wasting money on unsold goods can hurt both profits and customer trust. Many businesses face this challenge because they don’t forecast their inventory needs correctly. That’s where inventory forecasting steps in. Companies use different methods like EOQ and ROP to enhance their inventory management, incorporating both quantitative […]

Read More

Logistics Risk Management: What It Is, Types, and Implementation

Unexpected events can derail even the most efficient logistics network, making risk management in logistics essential. From natural disasters to supplier delays, risks pop up without warning. That’s why logistics risk management is no longer optional—it’s essential. Companies today face supply chain disruptions that can impact everything from raw materials to customer satisfaction. Identifying potential […]

Read More