Articles

Case Studies

Hu Huang: Bright Light in Global Trade

Hu Huang is director of international logistics and customs compliance at Kichler Lighting in Cleveland, which is among the top one percent of importers in the United States. She has worked for Kichler since 1988, and served in her current position since 2002. Responsibilities: Worldwide imports and exports, including direct imports to Fortune 100 companies; […]

Read MoreCintron Quenches Thirst For Order Management System

A Web-based OMS provides a shot of energy to Cintron’s inventory and order management processes.

Read More

Aerodynamic Trailer Add-ons Make Fuel Savings a Breeze

High transportation costs were a drag for Anderson Hay & Grain, until it installed aerodynamic trailer side skirts to increase fuel efficiency.

Read More

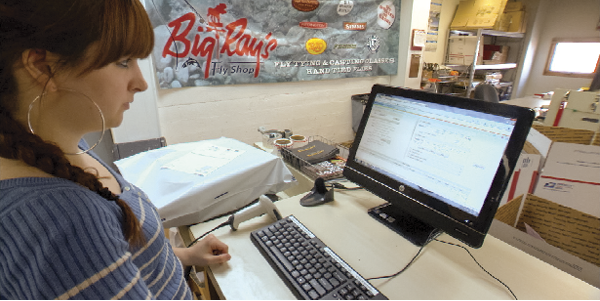

Bringing Supply Chain Visibility to the Last Frontier

A Web-based shipping tool helps Classic Alaska Trading Company tame the wilds of its inventory and fulfillment operations.

Read More

Matthew Wood: Finding a Cure for High Freight Costs

Matthew Wood is manager of the freight program, supply chain management, at Mayo Clinic in Rochester, Minn. He has held this position since 2012. Responsibilities: Managing freight expenditures for all items purchased by organizations within Mayo Clinic; helping departments find ways to reduce their freight costs; marketing those services to other healthcare organizations. Experience: More […]

Read More

Dino Lanno: Best in Glass

Dino Lanno has been senior vice president, supply chain at Safelite AutoGlass in Columbus, Ohio, since 2007. Responsibilities: Procurement, transportation, distribution, manufacturing, inventory management, and wholesale sales. Experience: Facilities engineer, WearEver Aluminum; product development engineer, Hamilton Beach Procter Silex; engineer manager, plant manager, WearEver Aluminum; regional warehouse manager, director of materials management, vice president of […]

Read More

Delivery Scheduling Relieves Loading Dock Bottlenecks

An online appointment scheduling system gave beer distributor Crescent Crown control over trucks pouring into its distribution center.

Read More

Inventory Optimization: A Natural Fit

A new inventory management system nurses Nature’s Best’s fulfillment operations back to health.

Read MoreLarry Montreuil: True Blue

Larry Montreuil has been director of supply chain management at JetBlue Airways in New York since 2003. Responsibilities: Strategic sourcing, contracts and purchasing. Experience: Supervisor, materials management, New York Air; manager, logistical planning and provisioning, Continental Airlines; director of purchasing, Trump Shuttle; director of purchasing, Queens Surface Corp. Education: B.S., aeronautical industrial technology, Arizona State […]

Read More

Going Green to Save Green

Can reducing environmental impact generate significant financial rewards? For Caterpillar, the proof is in the profits.

Read More

Jason Mathers: Carbon Slasher

Jason Mathers is senior manager, corporate partnerships at the Boston office of the Environmental Defense Fund (EDF), an environmental advocacy group. He has held this position since 2006. Responsibilities: Leading partnerships with Fortune 1000 companies to reduce carbon emissions in freight transportation while also reducing freight costs. Experience: U.S. Navy, USS Normandy, operations specialist, petty […]

Read More

Brian Morgan: Transportation Superconductor

Brian Morgan is director of logistics at Leviton, a manufacturer of electrical wiring devices, network and data center connectivity solutions, and energy management systems, based in Melville, N.Y. He joined the company in 2012. Responsibilities: Managing the transportation network and introducing technologies to improve transportation operations. Experience: Intern, Corvette workplace development team, General Motors; manufacturing […]

Read More

Sander Eth: Putting Green Principles Into Action

Sander Eth is senior vice president, supply chain at Bambeco, a Baltimore-based direct merchant specializing in ecologically friendly products for the home. He joined the company in 2012. Responsibilities: Inventory management, fulfillment center operations, and vendor compliance. Experience: Several in-store management positions, followed by corporate positions in inventory management, merchandising, and logistics and supply chain, […]

Read More

Cloud-Based WMS Fires Up Supermercados Supply Chain

Peruvian supermarket chain Supermercados feeds its need for DC network realignment with a SaaS WMS solution.

Read More

Improved Warehouse Operations: Cause to Celebrate

Party goods supplier Oriental Trading Company revamps its warehouse technology to keep pace with online sales.

Read More

Inventory Replenishment: A Push in the Right Direction

Close-out retailer Tuesday Morning uses a WMS to allocate and ship a constant stream of new products to stores, keeping customers happy every day of the week.

Read More

William Gregory: Into Africa

William Gregory has served as global supply chain coordinator at VT iDirect, in Herndon, Va., since 2012. VT iDirect is a global vendor of technology for satellite-based Internet Protocol (IP) communications. Responsibilities: International shipping, customs, and regulatory compliance; liaison with freight forwarders; subject matter expert for Middle East and Africa. Experience: Intern, Samuel Shapiro and […]

Read More

Victor Hougan: Finding a Love for Logistics

Victor Hougan joined Primus International, a Bellevue, Wash.-based Tier II supplier of engineered metallic and composite parts, kits, and assemblies to the global aerospace industry, in the fall of 2012. His role in its logistics operation is still evolving. Experience: Finish carpenter in the construction industry; computer technician; delivery coordinator, ISEC Inc.; warehouse manager, Elegant […]

Read More

An Appetite for Refrigerated Warehousing Improvement

When food company Bob Evans farmed out its warehousing and distribution operations, it engaged more than a provider—it found a true business partner that optimized its processes.

Read More

Michael Smyers: Molecular Logistics

Michael Smyers is associate director, logistics, at Amyris, a manufacturer of chemical products and transportation fuels made from renewable resources, based on an industrial synthetic biology platform. Smyers has worked at Amyris, in Emeryville, Calif., since 2010. Responsibilities: Global logistics, trade compliance, and sourcing. Experience: Internship, TranzAct Technologies; several operational and managerial positions culminating in […]

Read More