Web Cite City

WMS

3PL Central

3PL Central is a leader in cloud-based warehouse management system (WMS) solutions built to meet the unique needs of the 3PL warehousing community. Serving as the backbone of our customer’s operations, our platform aims to quickly transform paper-based, error-prone businesses into service leaders who can focus on customer satisfaction, operate more efficiently, and grow faster. Offering a comprehensive warehouse management platform, we endeavor to make it easy for 3PLs to manage inventory, automate routine tasks, and deliver complete visibility to their customers.

BW Design Group

Design Group provides Warehouse Management Solutions to clients of all sizes, across multiple industries. In addition to Infor CloudSuite WMS, we provide end-to-end enterprise and technology solutions including Enterprise Resource Planning, Quality Management, Product Lifecycle Management, Asset Management, and Factory Automation. We also provide a variety of Professional Services including warehouse evaluation and optimization, WMS software and implementations, integration to your ERP and PLM, operations planning and automated material handling systems.

Camelot 3PL Software

A market leader since 1987, Camelot 3PL Software provides Warehouse Management Systems (3PL WMS) exclusively for third-party logistics warehouses to streamline their operations, eliminate costs and increase service levels. Offering cloud (SaaS) and on-premise solutions, Camelot’s highly configurable solutions are ideal for small, medium and enterprise-level warehouses.

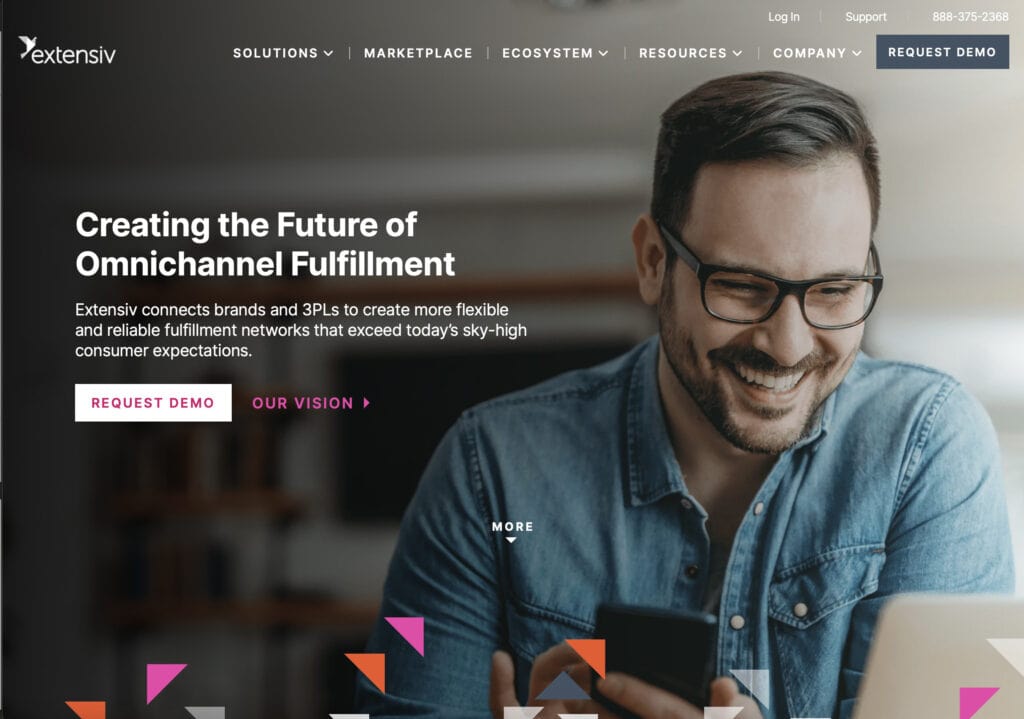

Extensiv

Extensiv 3PL Warehouse Manager is a cloud-based WMS designed for 3PLs to manage multiple customers, processes and billing schedules. We provide access to real-time information and integrate with EDI, barcode scanning, ecommerce shopping carts and more. Our WMS is designed to help 3PLs automate processes and bill items accurately, helping logistics providers satisfy customers’ need for updated information and increase profits through process automation. We integrate with QuickBooks, which allows users to synchronize items, inventory, purchase orders, and receipts.

Foxfire Software

http://www.foxfiresoftware.com

For over 20 years, Foxfire has specialized in Warehouse Management Software (WMS) serving distribution facilities across North and South America. Its WMS software is ideal for those wanting to optimize inventory levels, increase warehouse labor productivity, improve customer satisfaction, and reduce cycle times. With Foxfire warehousing software, customers can make their operations more efficient, more productive, and more profitable. For more information about a Warehouse Management System, contact Foxfire at 864-868-5243 or visit www.foxfiresoftware.com.

HighJump Software

HighJump Software is a global provider of supply chain management software that streamlines the flow of inventory and information from supplier to store shelf. More than 4,500 customers worldwide have transformed their supply chains using HighJump Software. HighJump Software solutions for distribution and logistics, direct store delivery, trading partner connectivity, mobility and manufacturing include: warehouse management systems, transportation management systems, route accounting systems, manufacturing execution, mobile sales, ERP data collection and the TrueCommerceTM EDI Solutions Platform.

Interlink Technologies

Discover the full potential of your warehouse with Warehouse-LINK® Warehouse Management Systems (WMS). Warehouse-LINK® utilizes barcode and mobile computing technology to support real-time distribution activities—Multi-Building/Company/Locations Management; Expiration, Lot/Batch/Serial Tracking, Raw Materials and Finished Goods; Characteristic Management (FIFO, ABC, UPCs); Location Management (cubic capacity, environmental, temporary, seasonal); Work Orders, Kitting, Cross Dock, Replenishment, QC, Wave Planning and Yard Management. Warehouse-LINK® integrates with business systems and material handling systems. Think Interlink for WMS expertise!

Iptor Supply Chain Systems

Iptor’s Warehouse Management solution directs and optimizes stock put-away based on real-time information about the status of bin utilization. It includes best-of-breed WMS and MES functionalities based on the latest Microsoft technology. Scalable, functional, easy-to-use, and simple to implement, Iptor’s WMS represents the lowest total cost of ownership and fastest ROI in the industry – guaranteed.

Made4net

Made4net provides best-in-class supply chain execution and warehouse management software for organizations of all sizes to improve the speed and efficiency of their supply chain. The company’s end-to-end SCExpert platform offers a robust WMS solution that enables real-time inventory visibility, labor management, and equipment productivity with performance analytics that drive faster, more accurate order fulfillment and improved supply chain efficiency. In addition to the best-of-breed WMS, the platform offers integrated yard management, dynamic route management, proof of delivery and warehouse automation solutions that deliver true supply chain convergence.

QSSI

We built QSSI around one important premise: anticipating challenges and opportunities down the pipeline can get you closer to a desired outcome. We aspire to provide you with insights into your business: employee profiles, supply chain relationships, delivery tracking, customer visibility, verification, and much more. But, data is just data without context, which is why we always start with the question, “What do you want to do?”

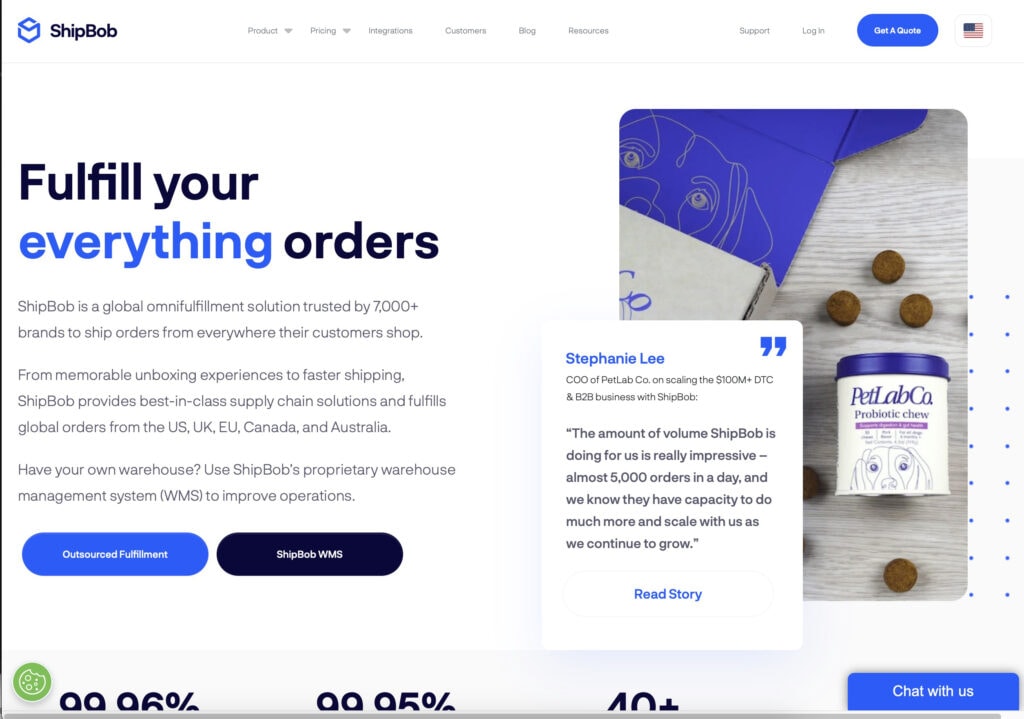

ShipBob

ShipBob WMS is an all-in-one fulfillment platform that combines WMS, IMS, OMS, TMS, and label generation software. Implement ShipBob’s world-class WMS in your own facility to improve transparency and control over operations, reduce errors, speed up fulfillment, and get time back to grow your brand.

SmartTurn Inc.

SmartTurn™ provides Web-based, on-demand inventory control and warehouse management solutions that deliver real-time, accurate visibility of inventory across single or multiple warehouses. Designed to deliver enterprise-class capabilities for small to medium-sized business at a fraction of the cost of traditional license and installed software. For one low, monthly fee you get unlimited users, access to all critical inventory and warehouse functions, built-in integration to QuickBooks and most CRM/ERP/POS systems. Powerful enough for 3PLs, manufacturers and wholesalers who need turn-key, customizable visibility for all your customers or trading partners. Create a new value curve for your business and improve your customer service levels instantly. See the demo now.