Web Cite City

White Glove

Echo Global Logistics

Echo Global Logistics, Inc. is a leading provider of technology-enabled transportation and supply chain management services. Headquartered in Chicago with more than 30 offices around the country, Echo offers freight brokerage and Managed Transportation Solutions for all major modes, including truckload, partial truckload, LTL, intermodal, temperature-controlled shipping and warehousing, and warehouse services. Named one of Newsweek’s Most Trusted Companies in America, Echo leverages its proprietary web-based and mobile app technology, analyzing data from its network of more than 50,000 transportation providers to help its 35,000 clients simplify the critical tasks involved in transportation management.

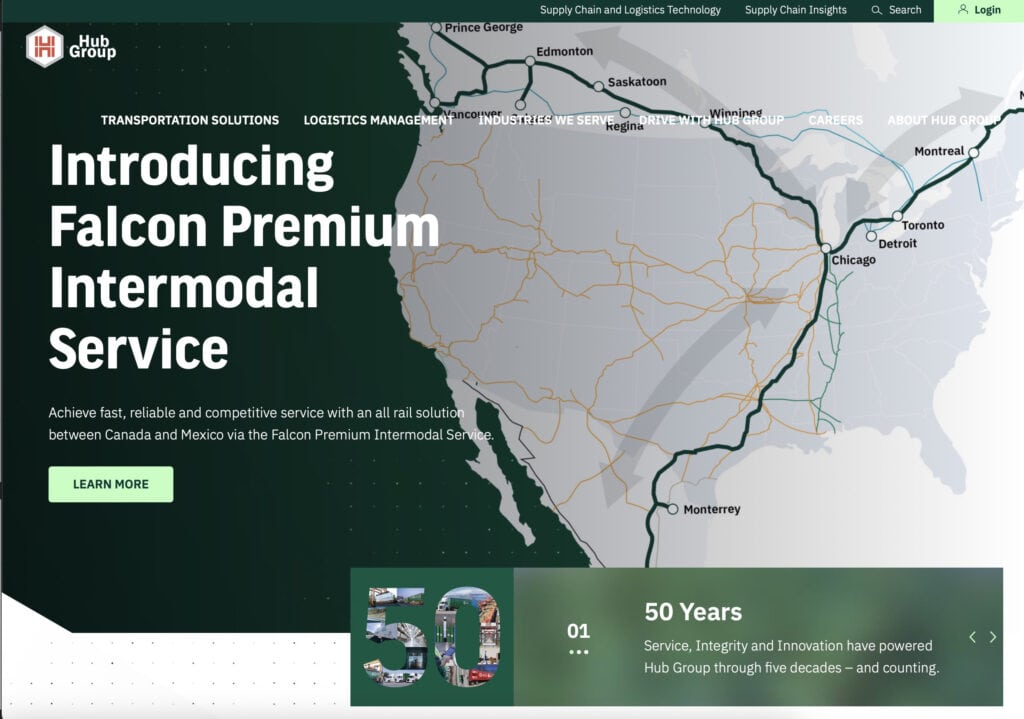

Hub Group

Hub’s extensive service network—built over many years—enables it to provide innovative transportation solutions that are versatile, flexible, and designed to deliver maximum efficiency. With this advantage, Hub Group is able to collaborate with customers daily to help them meet their transportation challenges. With intermodal, highway, and logistics transportation offerings, the Hub Network is your single-source provider—coast to coast, border to border. Visit the website to learn what Hub can do for you.